As an electronics service provider we offer much more than just contract PCB assembly!

With the development of complete OEM products for our customers in a variety of industries and the subsequent production by us as a supplier we particularly address medium-sized businesses with high demands with respect to the development and production of high-quality, technically complex component assemblies and equipment.

From product definition to final testing: we are able to offer you the full scope of services. In this you benefit from our long experience as a manufacturer of high-quality acoustic measuring instruments. Since 1990 we have been manufacturing electronic flat modules with state-of-the-art equipment utilizing all standard process technologies at our site in Leipzig, Germany.

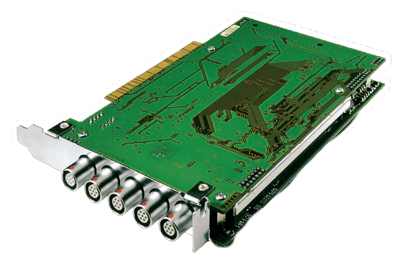

Our flat module production focusses on small and medium quantities with maximum PCB sizes of 250 mm x 450 mm in advanced technologies. Depending on your requirements, our equipment allows production using lead-free (RoHS-compliant) or lead-containing solder technologies.

We are able to process all standard package designs as:

- SMD (surface mount devices with circumferential solder fillet)

- THT (traditional, leaded devices for wave soldering)

- BGA (Ball Grid Arrays, matrix arrangement of the solder terminals with solder balls on a substrate)

The stated device types allow for double-sided or mixed PCB placement. SMD assembly is realized with fully automatic pick-and-place machines from MYDATA which offer an assembly capacity of up to 40,000 SMD devices per hour. THT devices are mounted with semi-automatic machines manufactured by Royonic. Our state-of-the-art production lane achieves an extremely low placement error rate. To safeguard zero-error production comprehensive assembly tests are required, which we may perform in our test laboratory based on your testing specifications. As part of our production service component assemblies are subject to extensive testing as initial tests, in-circuit tests, temperature shock testing in a climate chamber and automatic performance tests. Our in-house laboratory for climate, mechanical and EMC testing constantly monitors the quality of our products. The traceability for quality documentation is safeguarded with a Barcode serial number on each PCB and component assembly.

The following in-house equipment is available for the full testing of components and devices:

- Electrical performance test

- Pre-testing of electro-magnetic compatibility

- Climate chamber testing (-25°C to +125°C)

- Vibration test with shaker

- ISO 3744/45/46 Sound power measurement

- ISO 9614 Sound power measurement

To manufacture your assemblies reliably at optimal cost without expensive re-design we already provide support during the product and PCB design stage. Apart from the design we evaluate your bill of materials with respect to the availability of core components as well as cost savings through device optimization and standardisation. We also offer these engineering resources as individual services. The adjacent schematic illustrates our complete service portfolio as OEM partner for flat module assembly.

Test equipment design, CNC machining and mechanical prototyping

Apart from the development and production of electronic assemblies we also offer the construction and prototyping of mechanical assemblies. In this field we can claim the successful implementation of several challenging test devices and special tools, which have proven their design and production quality during continuous operation. Our prototyping services incorporate the design and manufacturing of complete test equipment for the electronics production including mechanics, electronics and pneumatics from one single source.

Among others we utilize the following CAD systems:

- mechanical design with PTC Creo 3.0 and AutoSketch 2D

- PCB design with Altium- and XL- Designer

Applicable data import formats are:

DXF,STEP, IGES, GERBER

Our service portfolio currently includes:

- Support for the definition of new electronic products

- Analogue and digital circuit design including simulation

- Software design for DSPs, controllers

- Design of complex customized circuits (FPGA, EPLD)

- PCB design (DS/DK, MLL, Starrflex, Flex)

- CAD design of electronic and mechanical component assemblies

- CNC manufacturing (milling, drilling, turning)

- Device production in small and medium quantities

- Mechanical, climate and EMC laboratory testing

- Sound and vibration measurements.